Auto Diagnose Gudie

Wednesday, February 23, 2022

Thursday, May 6, 2021

Sunday, April 25, 2021

Sunday, March 15, 2020

SVCI 2020 Diagnostic Software "mfc110u.dll is missing" Trouble Solution

Recently,one of obd360.com customer feedback that his SVCI 2020 tool can not work and get error massage "The program can't start because mfc110u.dll is missing from your computer.Try reinstalling the program to fix this problem."

Here UOBD2 tech team give the solution:

Method 1:

Run patch.

Right click the SVIC 2020 software icon on the desktop -> properties -> open file location -> run all the 4 programs inside.

Method 2

Download this patch to run.

https://mega.nz/#!YUpgTIrB!ewMLqDLJ_gmoteaX-uBRj5TwE-jwqOxd7WIvTIdBai0

Here UOBD2 tech team give the solution:

Method 1:

Run patch.

Right click the SVIC 2020 software icon on the desktop -> properties -> open file location -> run all the 4 programs inside.

Method 2

Download this patch to run.

https://mega.nz/#!YUpgTIrB!ewMLqDLJ_gmoteaX-uBRj5TwE-jwqOxd7WIvTIdBai0

Wednesday, August 8, 2018

Jaguar XJ Check Engine Light On Repair Guide

Another issue:

Jaguar XK / XKR ( X150 ) Passenger seat recline Repair

Troubleshooting:

After the vehicle is picked up, the test is verified to be faulty, the ignition switch is turned on, the engine is started, the engine is started smoothly, and the engine fault light on the instrument panel is lit, and the fault phenomenon does exist. Connect the fault detector and retrieve the fault code. The fault code is "B2139 Data mismatch (received data does not match expected data)", which means that the password does not match; "P0171-00 System too lean (bankl)", The meaning is that the cylinder group 1 is too lean; "P0174-00 System too lean (bank2)", which means that the cylinder group 2 is too lean; "U1262 SCP 01850" Communications bus fault", which means SCP U1850) bus Communication failed.JLR Key Programmer

Analysis of the fault code shows that the fault codes associated with the fault phenomenon are P0171 and P0174. The relevant data stream is read. The data flow shows that the long-term fuel correction values of cylinder groups 1 and 2 at idle are 20.3%, the short-term fuel correction value of cylinder group 1 is 3.91%, and the short-term fuel correction value of cylinder group 2 is 5.47%. . However, when the accelerator pedal is depressed, the engine speed is increased. As the engine speed increases, the long-term fuel correction values of the cylinder groups 1 and 2 gradually return to normal, but the short-term fuel correction value of the cylinder group 2 is always larger than that of the cylinder group 1.

According to the above inspection results, combined with the maintenance experience, it is considered that there is a high possibility of leakage in the engine intake line. Considering that the short-term fuel correction value of the cylinder group 2 is always larger than that of the cylinder group 1, it is suspected that there may be a leak in the intake line on the side of the cylinder group 2. Then, the intake line on the side of the cylinder group 2 is inspected, and it is found that there is a leak in the intake switching valve on the side of the cylinder group 2. However, according to the maintenance experience, the leakage of the pipeline on this side does not make the long-term fuel correction value of the whole system significantly higher.

Next, the maintenance personnel inspected the activated carbon canister solenoid valve and found that the activated carbon canister solenoid valve was still open at idle speed. Disconnect the pipe connected to the activated carbon canister at the throttle valve, and grasp the interface on the throttle side by hand to observe the change of the long-term fuel correction value of the cylinder groups 1 and 2 at the idle speed, and find the long-term fuel of the cylinder groups 1 and 2. The correction value has changed to 18.8%. Although it has improved better than the previous test results, the air leakage fault has not been completely eliminated.

Check the various ports of the pipeline between the air filter and the intake manifold, no air leakage, and check the brake vacuum tube, the crankcase forced ventilation line, the fuel pressure regulating valve vacuum line and the activated carbon canister solenoid valve vacuum tube. Road, no abnormalities. Troubleshooting is deadlocked.

After careful consideration, the fault apparently has air that has not been counted in, causing the system to correct the amount of fuel injected. The maintenance personnel again inspect the intake line again. When the air cleaner was removed and the intake line between the throttle and the throttle was inspected, it was found that the back of the intake pipe was aged and cracked.

Troubleshooting: Replace the intake line and cylinder group 2 intake switching valve, commissioning, troubleshooting.

Crack JLR SDD V151 free download on Win7 8 10 – No pass

Wednesday, July 18, 2018

VIDENT iLink400 Complete Data List Introduce

VIDENT iLink400 Scanner Complete Data List menu lets you view all live PID data from a selected system.

1. Scroll with the up and down arrow keys to highlight a line, if the One Graphic on the bottom is highlighted, it indicates graphing is available for the selected line. Press the function key One

Graphic to display the PID graph.

2. Press the function key Two Graphics to display two PID graphs in one screen.

3. Press the function key Merge Graph to display two PID plots in one coordinate for easy and intuitive diagnosis.

4. To record the data to memory of the scan tool, use the function key SAVE, and press Stop

Saving to stop recording at any time.

5. Press Text to return to text viewing of PID data.

6. Select Pause to suspend collecting data from the scan tool and use the Start key to resume collecting data.

7. Press the ECS key to return to the previous menu.

src:http://www.uobdii.com/wholesale/vident-ilink400-scan-tool-single-maker.html

1. Scroll with the up and down arrow keys to highlight a line, if the One Graphic on the bottom is highlighted, it indicates graphing is available for the selected line. Press the function key One

Graphic to display the PID graph.

2. Press the function key Two Graphics to display two PID graphs in one screen.

3. Press the function key Merge Graph to display two PID plots in one coordinate for easy and intuitive diagnosis.

4. To record the data to memory of the scan tool, use the function key SAVE, and press Stop

Saving to stop recording at any time.

5. Press Text to return to text viewing of PID data.

6. Select Pause to suspend collecting data from the scan tool and use the Start key to resume collecting data.

7. Press the ECS key to return to the previous menu.

src:http://www.uobdii.com/wholesale/vident-ilink400-scan-tool-single-maker.html

Tuesday, May 29, 2018

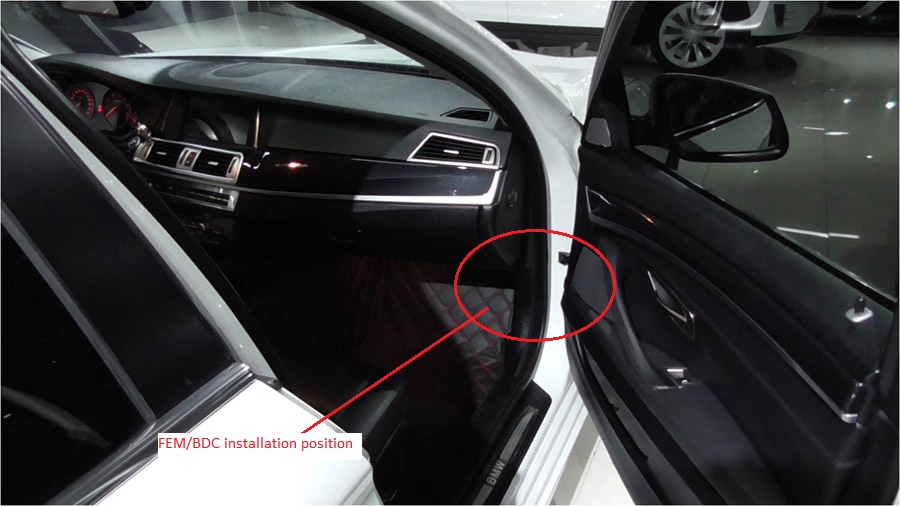

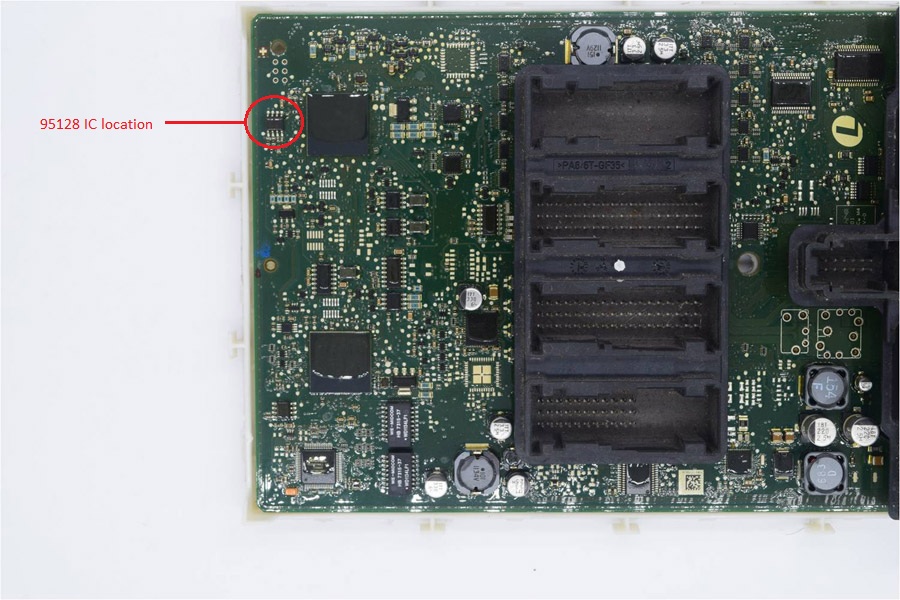

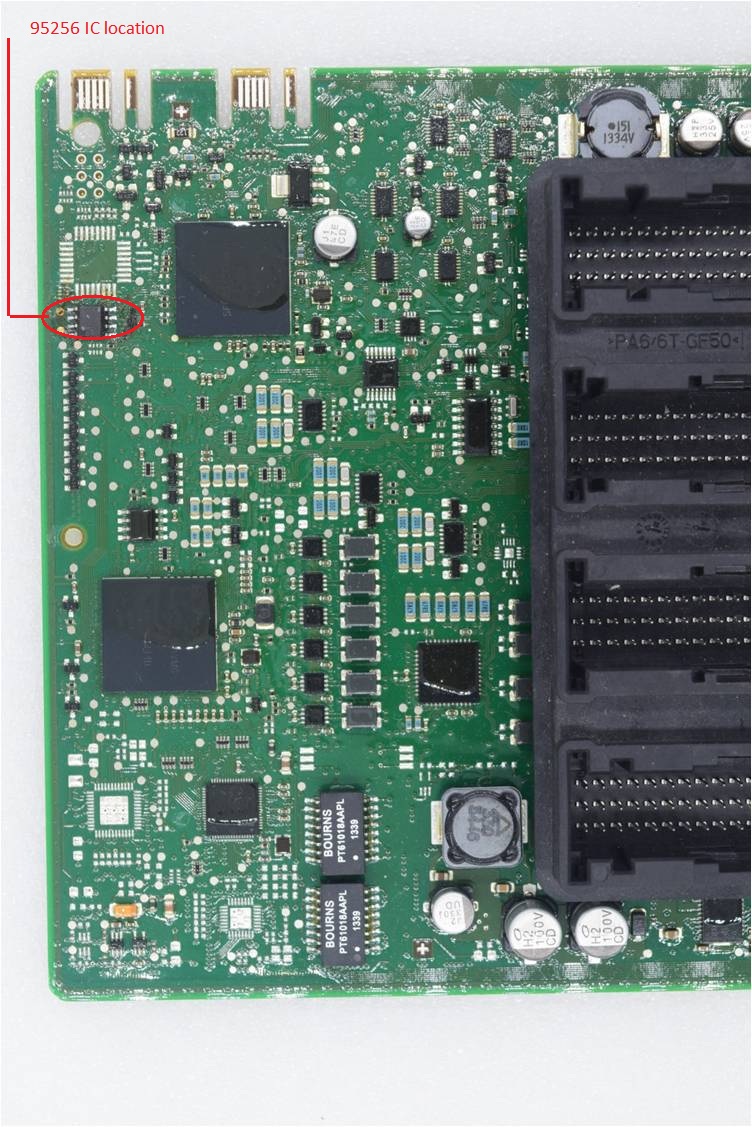

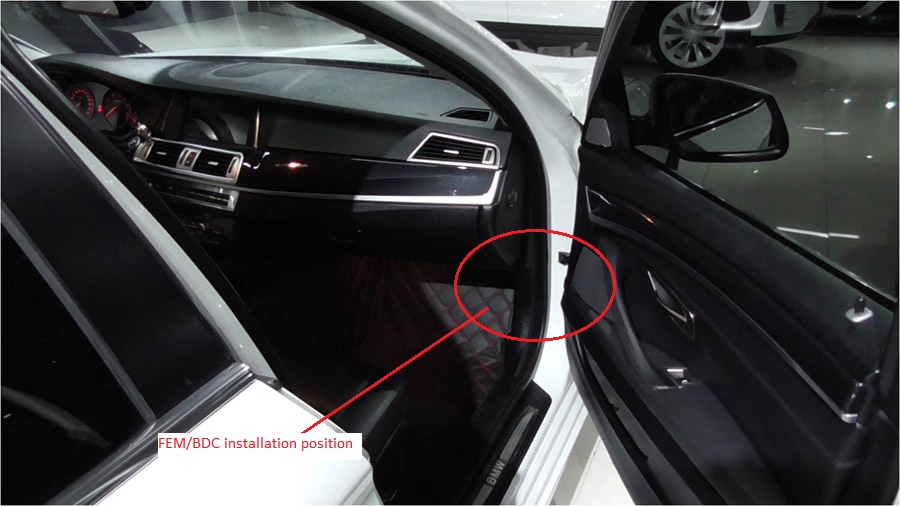

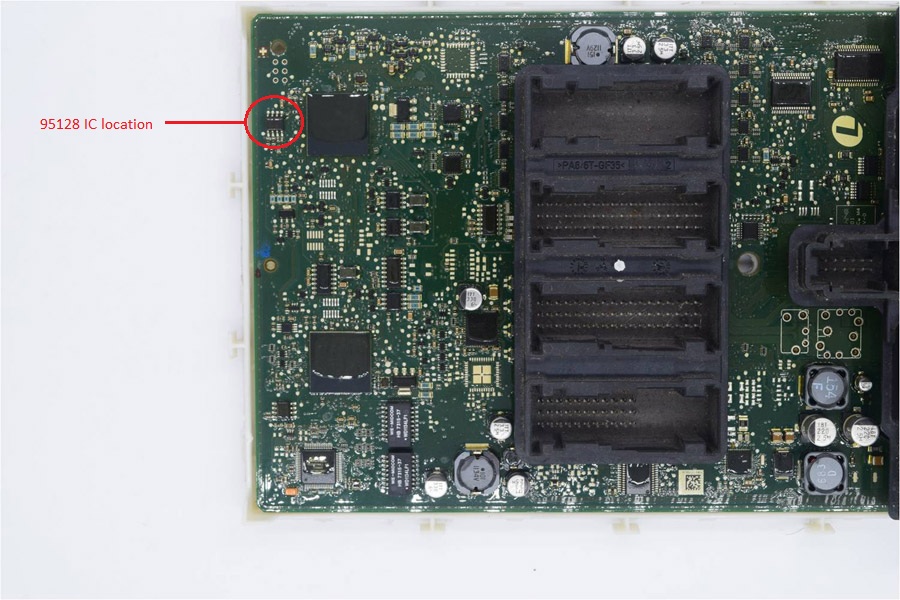

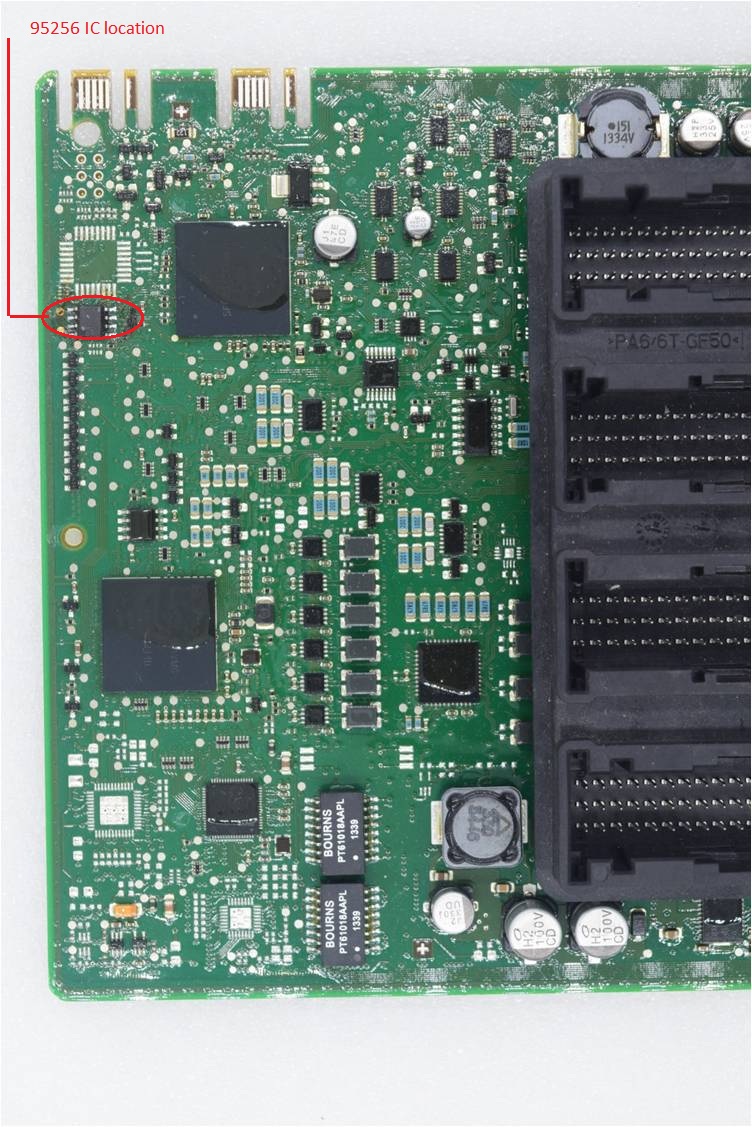

How to Perform BMW FEM/BDC Key Learning by CGDI BMW

CGDI BMW FEM BDC key learn is

in the dismantling method instead of OBD method. Then you have to know

the FEM/BDC system location, 95128 IC location, 95256 IC location and

Key learning position, read the detail in the below parts.

CGDI Shop

CGDI Benz Programmer

That’s all.

Value bundle:

CGDI Prog BMW MSV80 plus BWM FEM/BDC Authorization.

CGDI Shop

- BMW FEM/ BDC installation location.

CGDI Benz Programmer

- 95128 IC location

- 95256 IC location

- Key learning position

That’s all.

Value bundle:

CGDI Prog BMW MSV80 plus BWM FEM/BDC Authorization.

Subscribe to:

Posts (Atom)